Auto Repair Shop In Plainfield, IL

How to Repair a Cooling System in 2026 Tips and Tricks?

In the ever-evolving landscape of mechanical engineering, cooling system repair remains a crucial area for maintenance and efficiency. Johnathan R. Lee, a noted expert in HVAC systems, once stated, "A well-maintained cooling system is the backbone of any efficient operation." His insight highlights the importance of proper care and timely repairs in this essential domain.

Cooling systems can fail unexpectedly, causing significant downtime. The reasons for malfunctions can vary widely, from coolant leaks to faulty fans. It's essential to address these issues promptly, ensuring that the system operates effectively. Even skilled technicians sometimes overlook basic checks, leading to larger problems down the line.

In 2026, the approach to cooling system repair will demand innovative techniques and keen attention to detail. Professionals need to be equipped with the right tools and knowledge to adapt to new technologies. A proactive mindset can make a difference in avoiding pitfalls. As we delve into tips and tricks for repairing cooling systems, the focus will be on practical solutions that anyone can apply, enhancing performance and reliability.

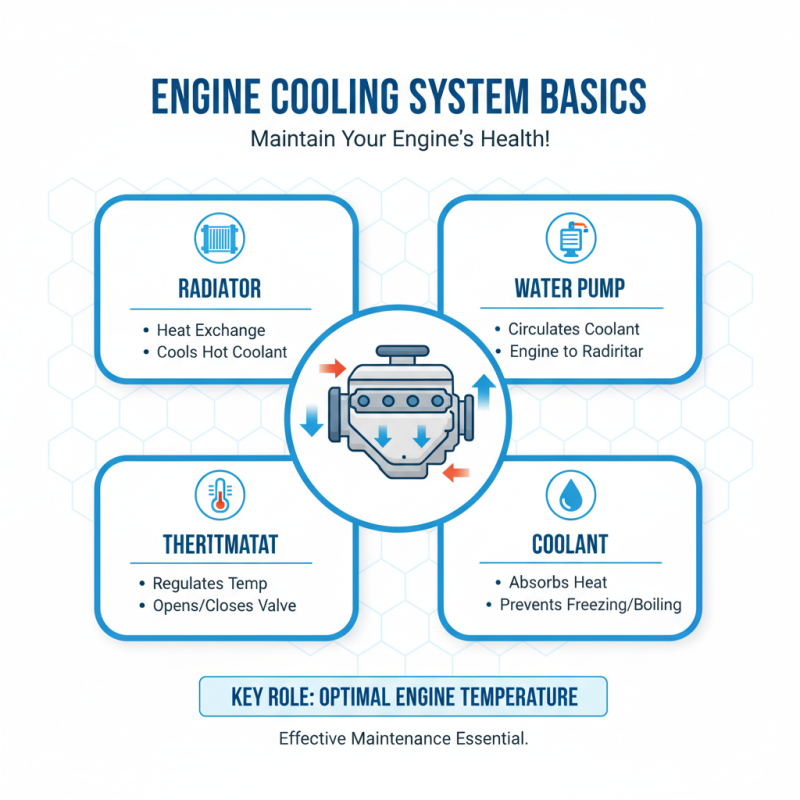

Understanding the Basics of a Cooling System and Its Components

Understanding the basics of a cooling system is essential for effective maintenance. A cooling system works by transferring heat away from critical engine components. It comprises several key components: the radiator, water pump, thermostat, and coolant. Each part plays a vital role in keeping the engine temperature within optimal ranges.

Regularly checking coolant levels is important. According to a report by the Automotive Industry Association, nearly one-third of cooling system failures are due to low coolant levels. When coolant evaporates or leaks, it can lead to overheating. Inspect hoses and connections for any signs of wear. Replace any damaged parts immediately to avoid costly repairs later.

Tip: Schedule regular coolant flushes. Over time, coolant can become dirty and ineffective. A flushing can help extend the life of your cooling system. Another tip is to monitor engine temperature closely. If the gauge rises too high, stop immediately. Continuing to drive can cause severe damage. These simple steps could save you from more significant issues down the road.

Common Issues Faced by Cooling Systems and Their Symptoms

Cooling systems are vital for maintaining optimal temperatures in various environments. However, they often face common issues. Understanding these problems can lead to effective solutions. According to industry reports, nearly 30% of HVAC systems experience inadequate cooling due to airflow restrictions.

A typical symptom of airflow issues is uneven cooling throughout spaces. Rooms may feel warmer than others. Dust or debris obstructing vents can cause this. A simple tip is to regularly clean air filters and check for blockages. Keep an eye on ductwork too. Small gaps may lead to significant air loss.

Another frequent concern is refrigerant leaks. Reports indicate that systems with low refrigerant levels can lose efficiency by 20-30%. Symptoms include hissing sounds or ice buildup on coils. If you notice these signs, consider seeking professional help to assess the situation. Regular maintenance checks can also preempt many of these issues.

Monitoring system performance is crucial. Implementing these tips can help mitigate problems before they escalate. Regularly observing temperature fluctuations or unusual noises can alert you to potential failures. A proactive approach is key to ensuring your cooling system operates efficiently.

Common Issues Faced by Cooling Systems and Their Symptoms

Step-by-Step Guide to Diagnosing Cooling System Problems

Diagnosing cooling system problems can be tricky. Start by checking the coolant level. Low coolant can cause overheating. Use a dipstick to measure it. If it’s low, there may be a leak. Look for puddles under the vehicle. Inspect hoses for cracks or wear. Replace any damaged parts.

Next, examine the radiator. A blocked radiator can hinder cooling efficiency. Remove debris or dirt that may obstruct airflow. Use a soft brush for cleaning. Don’t forget the thermostat, too. It can fail and lead to engine overheating. Test it in boiling water; if it doesn’t open, consider replacing it.

While these steps are straightforward, issues may arise during your repair attempt. You might reassemble and find a part doesn’t fit right. Mistakes can happen, which is part of the learning process. Keep notes on what you did. Each attempt makes you a better mechanic. Don't rush through the process. Take breaks if frustration sets in. This practice can lead to better outcomes in the long run.

Effective Repair Techniques for Cooling System Components

Repairing a cooling system requires a comprehensive understanding of its components. Effective techniques can often save time and reduce costs. According to a 2022 industry report, approximately 30% of cooling system failures stem from clogged filters and worn-out fans. Regular monitoring can prevent these issues. Cleaning components regularly boosts efficiency and extends the lifespan.

Understanding common failure points is crucial. A malfunctioning thermostat can lead to overheating. Surprisingly, many overlook this small part. Simplifying repairs starts with proper diagnostics. Data shows up to 60% of repairs are unnecessary if initial assessments are thorough. Investing in diagnostic tools might seem costly, but it pays off in the long run.

Pay attention to coolant leaks. Even small drips can signal bigger problems. Repairing hoses and connections is often a simple fix. However, many delay this repair. Such procrastination can result in extensive damage, leading to higher repair costs. Sometimes, a quick patch isn’t sufficient. It’s necessary to evaluate the condition regularly. Make these repairs a priority for effective cooling system management.

Preventive Maintenance Tips to Enhance Cooling System Longevity

Maintaining a cooling system is crucial for its longevity. Regular checks can prevent costly repairs. Start by inspecting the coolant levels periodically. Low coolant can lead to overheating. Ensure hoses and connections are secure. Look out for cracks or leaks that could compromise efficiency.

Cleaning the condenser and evaporator coils is essential. Dust and debris can block airflow and reduce cooling performance. Use a soft brush or a vacuum for cleaning. Make sure the area around the unit is clear of obstructions. This simple step can enhance airflow and system efficiency.

Consider checking the thermostat settings. Incorrect settings may strain the system unnecessarily. Regularly recalibrate if needed. Don't forget to analyze the air filters. Replace them regularly to maintain good airflow. Neglecting these tasks can lead to breakdowns. Reflect on your routine; it may need adjustments. Continuous maintenance is key to a reliable cooling system.

How to Repair a Cooling System in 2026 Tips and Tricks? - Preventive Maintenance Tips to Enhance Cooling System Longevity

| Maintenance Task | Frequency | Tips |

|---|---|---|

| Check Coolant Levels | Monthly | Use manufacturer-recommended coolant; ensure mixture is correct. |

| Inspect Hoses and Belts | Every 3 months | Look for cracks or wear; replace if necessary to prevent leaks. |

| Clean the Radiator | Annually | Remove debris and check for any blockage; flush system if needed. |

| Test Thermostat Function | Every 6 months | Ensure it opens and closes at the correct temperatures. |

| Flush Cooling System | Every 2 years | Replace old coolant with fresh coolant to prevent issues. |

| Check for Leaks | Monthly | Inspect the area under the vehicle for coolant spots. |

Related Posts

-

Understanding the Essential Steps for Effective Cooling System Repair

-

How to Effectively Repair Your Cooling System: Step-by-Step Guide

-

Essential Guide to Mobile Transmission Repair Services and Tips for Vehicle Longevity

-

How to Perform Differential Repair for Your Vehicle Efficiently?

-

How to Perform a Tuneup for Your Car to Enhance Performance and Longevity

-

10 Best Places That Rebuild Transmissions for Quality Service

Contact Us

Service Area

Plainfield, 60585, 60544, 60586, Naperville, 60564, Bolingbrook, 60490, 60440, Romeoville, 60446, Will, Kendall, DuPage, Counties. Our auto repair shop in Plainfield, IL, has been serving the local area plus all surrounding Chicagoland since 1978.

Specialties

• Computer Diagnostic • Brake Shop • Engine Replacement • Transmission Rebuild • Clutch Replacement • Differential Rebuild • Suspension Shop • Steering • Shocks & Struts • Heating & Cooling • Electrical • Exhaust Shop • Catalytic Converter Replacement • Alignment • Domestic & Foreign Vehicle Service • Auto Repair In Plainfield, IL • Auto Repair Shops Near Me • Towing Service Near Me